Is it worth changing the culture of product development - preparing for the standard during the R&D?

- Victor Gorenstien

- 25 בינו׳ 2024

- זמן קריאה 2 דקות

Early pre-compliance electromagnetic compatibility (EMC) and Safety testing can be a strategic and cost-effective approach to ensure that a product complies with EMC/EMI and Safety requirements before the final compliance testing phase. Here are several ways in which early pre-compliance testing can help save money and time on final product testing and the bill of materials (BOM):

Identifying Issues Early: Pre-compliance testing allows you to identify potential EMC/EMI issues during the development phase. By detecting and addressing these issues early in the design process, you can avoid expensive changes and modifications later on.

Reducing Iterative Testing: Without pre-compliance testing, a product may undergo multiple rounds of full compliance testing, leading to increased testing costs and potential delays. Identifying and addressing EMC/EMI issues early can significantly reduce the need for iterative testing, saving both time and money.

Optimizing Design Iterations: Pre-compliance testing provides feedback on the EMC/EMI performance of various design iterations. This information allows designers to make informed decisions to optimize the product's EMC/EMI performance without going through the full compliance testing process each time.

Minimizing Design Revisions: Early identification and resolution of EMC issues help minimize the need for major design revisions. This can result in a more streamlined development process, reducing the time and resources required to bring the product to market.

Avoiding Last-Minute Fixes: Pre-compliance testing helps prevent last-minute EMC/EMI/Safety issues that may arise during final compliance testing. Addressing these issues early avoids the need for rushed and potentially costly fixes as the product approaches the production stage.

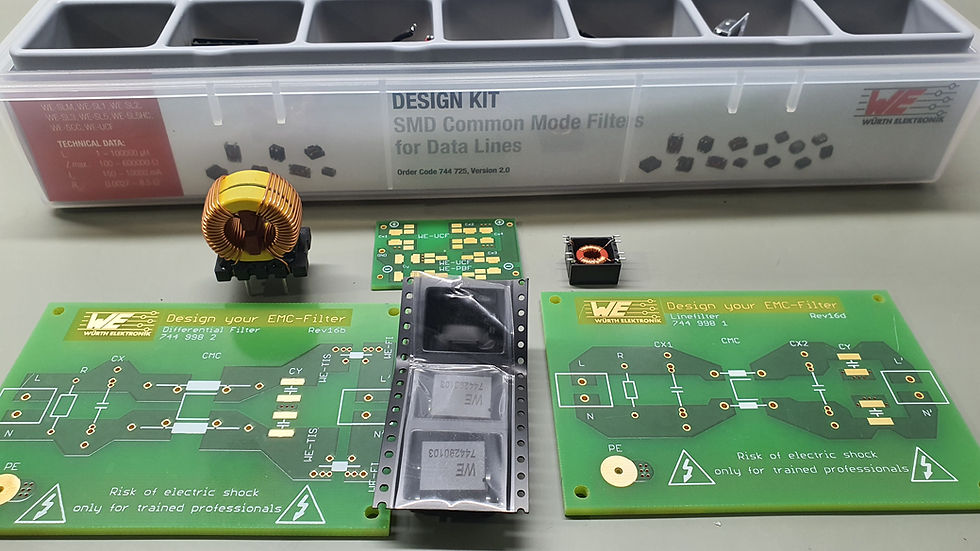

Reducing BOM Costs: Pre-compliance testing allows for the optimization of components and materials used in the design. By selecting EMC-compliant components early in the process, you can avoid costly late-stage changes to the bill of materials. On board(PCB) EMC/EMI parts(filters/ferrites/chokes) always cheapper than on cables/connectors/outside EMC/EMI parts.

Enhancing Product Reliability: Identifying and addressing EMC/Safety issues early can contribute to overall product reliability. A more robust and EMC/EMI-compliant design is likely to have fewer performance issues and failures during final compliance testing, resulting in a more reliable product.

Shortening Time-to-Market: By streamlining the testing and development process, pre-compliance testing can contribute to a faster time-to-market. This is crucial in competitive industries where being the first to market can provide a significant advantage.

Meeting Regulatory Deadlines: Pre-compliance testing ensures that a product is more likely to meet regulatory requirements upon final testing. This reduces the risk of missing deadlines due to unexpected compliance issues.

In summary, investing in early pre-compliance EMC/EMI/Safety testing can result in substantial cost and time savings by identifying and addressing potential issues before the final compliance testing stage. It contributes to a more efficient and streamlined product development process, ultimately leading to a more cost-effective and timely market launch.

תגובות